SF-320/360C Adsorption Type Single Facer Corrugation Machine

Functions and Features

01

7 Jan 2019

- SF-320/360C adsorption type single corrugated machine, corrugated roller φ320/360mm. The upper and lower corrugated rollers are made of high-quality chromium molybdenum alloy steel, with a hardness of HRC50-60 degrees, and the surface is grounding.

- Automatic idling device of gluing roller, pneumatic moving glue tray, electric glue separation adjustment device, and core paper electric spray device.

- The pressure roller and lower corrugated roller, as well as the upper glue roller and lower corrugated roller, are all pneumatically controlled, and the gap between the upper glue roller and the glue scraper roller is electrically micro adjusted.

01

7 Jan 2019

- The gap between glue roller and the glue scraper roller is controlled by a displacement device, and a human interface displays numerical values. The electric micro adjustment of glue amount ensures the required glue amount for the corrugated machine to operate at high and low speeds, ensuring the stability of the single corrugated paper quality.

- The glue roller and glue quantity roller are designed to slide and disassemble in groups with guide rails. The corrugated roller and bearing seats at both ends can be lifted and replaced in groups, reducing maintenance time.

- Main variable frequency motor, independent gearbox, three Shaft-driven, the acceleration and deceleration of the corrugated machine are controlled by the frequency converter, so as to save energy (electricity) and leave a communication joint for future production.

The corrugated carton box printing machine technical Parameters

Model |

320C |

360C |

Design speed |

160m/min |

200m/min |

Effective width |

1400-2200mm |

1600-2500mm |

Main corrugated roller |

φ 320mm |

Φ360mm |

Power appro. |

50KW |

50KW |

Steam pressure |

0.6—1.2Mpa |

0.6—1.2Mpa |

Other specification optional according to the demand.

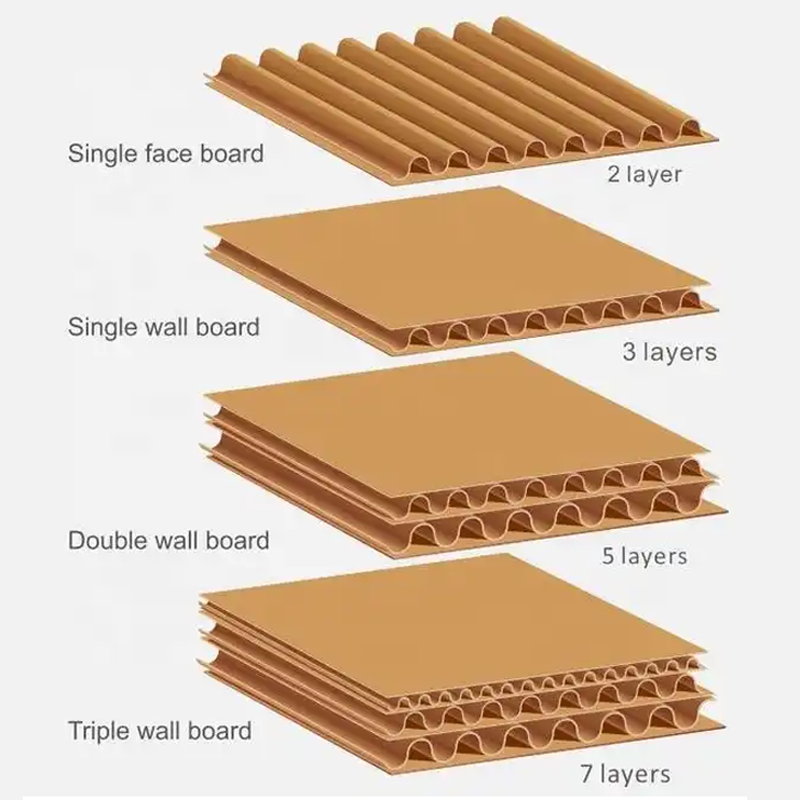

The Finished Cardboard You Can Get from the Corrugation Machine and the Application

01

2018-07-16

- The corrugated machine makes the 2 ply carboard during the corrugation production line

01

2018-07-16

- Several sets of corrugation machine you can combined to 3 ply, 5 ply, 7ply corrugated cardboard

01

2018-07-16

- Then printing slotting die cutting the cardboard to get the finished regular shape or special shape carton box

The Single Facer Corrugation Machine for Production Line Show

01

2018-07-16

- Strong and stable running and perfect for the high speed cardboard production line

01

2018-07-16

- High speed cardboard production line with 3 layer, 5 layer, 7 layer corrugated cardboard

01

2018-07-16

- Independent gear box, Universal joint transmission structure

01

2018-07-16

- touch screen display and operation of the encoder transmission coating gap, high accuracy.

The Raw Materials Need for the Corrugated Machine

01

2018-07-16

- Corn starch

01

2018-07-16

- Caustic soda

01

2018-07-16

- Borax