Roller Press Die Cutting Creasing Machine with Platform

Functions and Features

01

7 Jan 2019

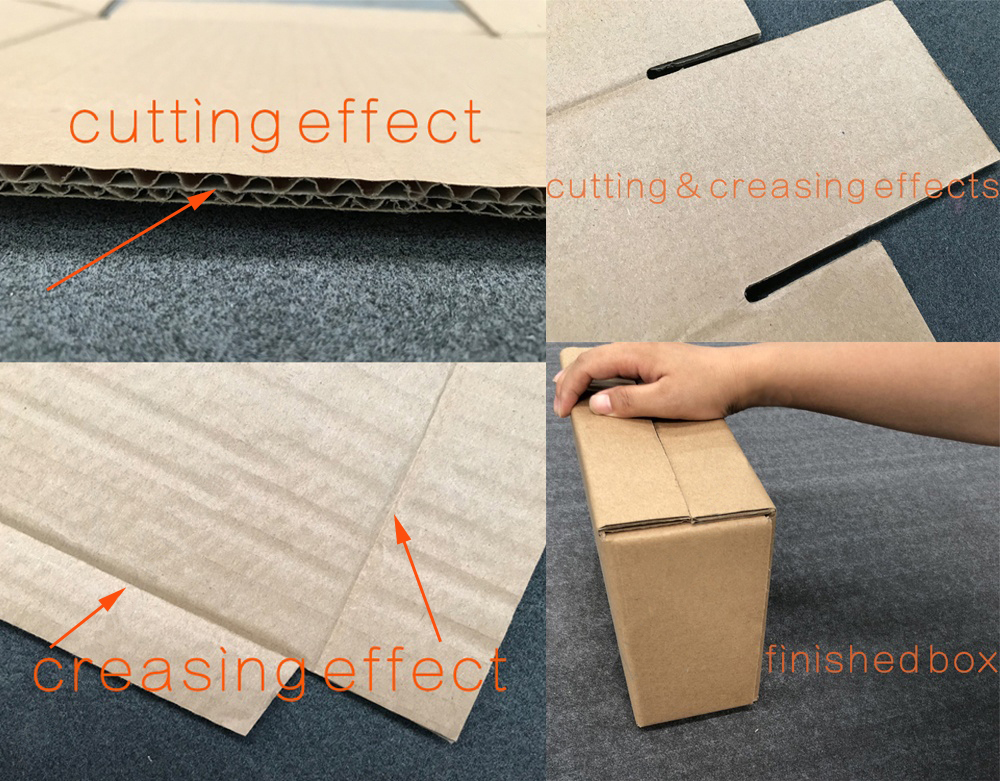

- It can finish the cutting of edge, corner, punching, slotting, creasing etc in one time; stable and accurate. No burr, clear and neatness and easy for operation.

01

7 Jan 2019

- Two workers is enough for operation, input the value and automatic transmission by fixed time; also can choose manual inching transmission, easy and safety.

The flat table die cutter machine need work together with cutting die.

technical Parameters

Model |

Cutting width |

Suggested Max die cutting size |

Speed |

Power |

Machine size (mm* mm* mm) |

Weight |

MQJ-1200 |

1200mm |

800*1000 mm |

0-30 sheets/min |

1.5 kw |

3500*1500*1250 |

650 kg |

MQJ-1400 |

1400mm |

1000*1000mm |

0-30 sheets/min |

1.5 kw |

3500*1700*1250 |

750 kg |

MQJ-1600 |

1600mm |

1200*1500 mm |

0-30 sheets/min |

2.2 kw |

4500*1900*1250 |

850 kg |

MQJ-1800 |

1800mm |

1400*1700 mm |

0-25 sheets/min |

2.2 kw |

5000*2100*1250 |

900 kg |

MQJ-2000 |

2000mm |

1600*1900 mm |

0-25 sheets/min |

2.2 kw |

5300*2300*1250 |

1200 kg |

MQJ-2200 |

2200mm |

1800*2000 mm |

0-25 sheets/min |

2.2 kw |

5500*2500*1250 |

1400 kg |

MQJ-2500 |

2500mm |

2100*2700 mm |

0-20 sheets/min |

3 kw |

7000*2850*1250 |

1800 kg |

Application

Usage

A die is a tool, usually made of metal, that cuts material (paperboard, plastic, fabric, adhesive, and many more) into pieces that are identical in size and shape. Die cutting benefits many industries because it offers different advantages depending on the type of project.

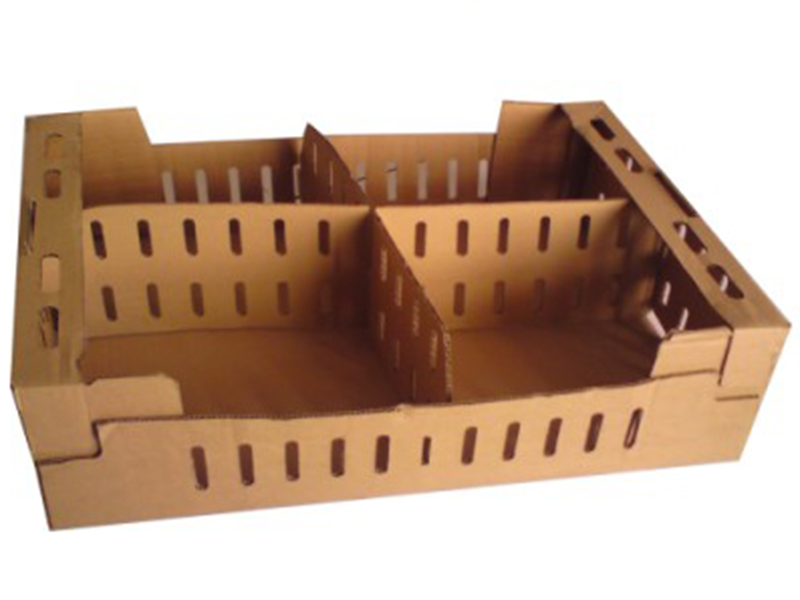

The flat bed die cutting machine is widely use for the big sheet cardboard, PP hollow board, plastic, leather etc die cutting and creasing. Good quality and affordable prices have won the favor of many customers. Different shapes are easy to get by changing the wood die. Many recycle company use it to remake the carton box such as pizza box, fruit box, courier box etc.

Die Cutting Type and choice

Maybe you're curious about the differences between flatbed die cutting, rotary die cutting, and laser die cutting methods. Here's a brief overview of each:

1. Flatbed roller die cutting: use the roller to press the materials to the wood die to cut the demand shapes as demand.

2. Flatbed die cutting: use the hydraulic or mechanical flatbed press to push down on a blade to cut the material into the desired shape.

3. Rotary die cutting: A round wood die with blades mounted around the entire roller to cut shapes of material in a circular motion, effectively produce many identical shapes.

4. Laser die cutting: Uses a laser instead of a steel blade to sear materials and easily create complex shapes in a variety of materials, but some materials and adhesives may be destroyed in the process.

Flat bed die cutting is Simple but very useful. Flatbed die cutting is often the preferred method for many materials and the cutting dies placed in a hydraulic press which allows cutting of thick and sheet materials. The wood die can be changed very easily and quickly. It is the ideal machine for the low-volume production.

Rotary die cutting is large production choice. The round wood die installed on the round die cutting roller, it can continuous shape die cutting and delivery out the materials, especial in the carton box making process. Rotary die, known by their durability, can die cut the large quantity of materials without change.

Laser die cutting is no wood die demand. no contact with the material, laser die cutting uses a high-speed laser to cut the materials. It’s a highly repeatable process that allows tiny details to be cut accurately. No need to make the wood die and will save lots of cost when make the shape samples.