Hydraulic Shaftless Mill Roll Stand for Paper Roll

Functions and Features

01

7 Jan 2019

- The structure is double shafts with symmetrical four arms, it can support two rolls of raw paper at the same time. In this way, paper can be easily changed without stopping the machine.

- Through hydraulic control, the paper roll can be clamp-loose, up-down, centering and corrected.

- Adopting the multi-point brake device and automatic expansion paper clamping to reduce paper waste.

01

7 Jan 2019

- Effective width of the base paper: 1200-2800mm, and Max paper roll diameter: 1500mm.

- Maximum support weight: V5B: 2.5T/V6B: 3.5T.

- Spindle diameter: φ 242/ φ 270mm

Technical Parameters

Model |

1600-3000 |

Working way |

Hydraulic way |

Max paper clamping width |

1600mm to 3000mm |

Min paper clamping width |

900mm |

Max paper roll diameter |

¢1500mm or customized |

Single side max loading weight |

2000kgs to 5000kgs |

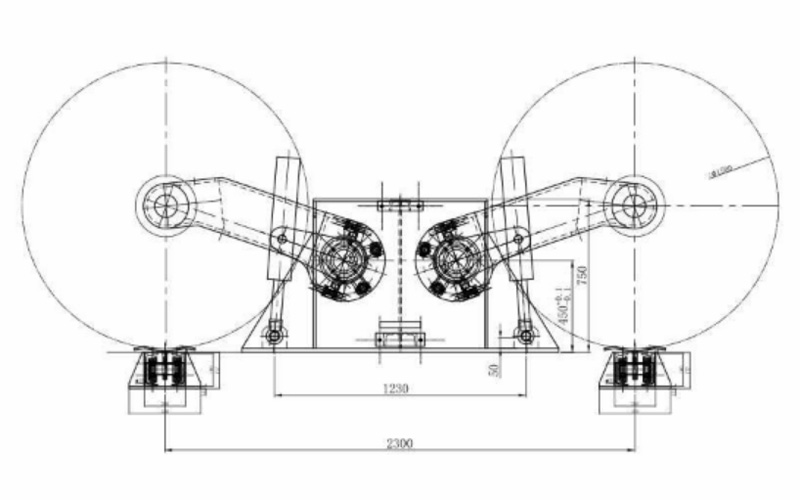

The hydraulic roll stand drawing

Bestice hydraulic paper roll unwinder with the multi point break system ( 3 points and 6 points) is a stong and durable reel stand. The independent movement of individual arms give the better control for adjustment and it is safety and flexibitiy for operation. The width of clamping the paper can customize to meet the corrugated line requirement.

The tension is pneumatic braking controlled. In addition, it can also be made under on-line control together with the paper splicer in the corrugation line. Our hydraulic paper mill roll stand is equipped with two sets of paper feeding trolleys which push paper roll to the given position from two sides to load the paper roll easily. And the railway need to entire bury under the ground and the main structure is welded with the 16# channel steel for firm and durable.