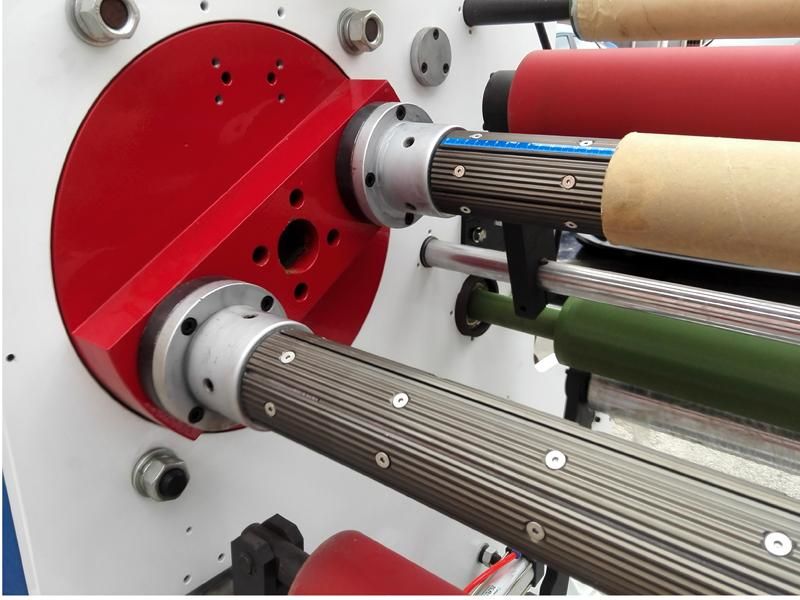

Double Shaft Automatic Rewinding Machine

Rewinding machine Features

- Separate loading system, automatic correction.

- Adopt PLC and touch screen, easy operation; Length and tension setting in the touch screen.

- Finish roll flatten device which eliminate the wrinkle and bubble phenomenon and make sure the finish roll smooth.

- Overturning device adopts servo motor, stable and precise.

- Adopt patent rotary automatic air inflate and deflate system, stable and fast.

tape rewinding slitting and cutting machine

| Operation width | 1000mm/1300mm/1600mm |

| max unwinding diameter | 800mm |

| max rewinding diameter | 300mm |

| rewinding speed | 120m/min |

| Machine power | 4kw |

| Unwinding shaft | 3'' pneumatic shaft |

| Unwinding tension | Pneumatic brake |

| rewinding tension | 5KG magnetic brake |

The corrugated carton box printing machine technical Parameters

- Unwinding part by pneumatic brake

- Double shafts rewinding part by magnetic brake

How To Maintain The Rewinder Daily

The rewinder is a kind of equipment used for paper, film,adesive tape etc. Its purpose is to rewind the tape rolls (called jumbo rolls) produced by the coating machine in turn, and the tape is rewound to make finished tape roll before leaving the factory. At present, it has become a development trend in the papermaking machinery industry to use AC drive instead of DC drive for rewinders.

The rewinding machine must be operated by fixed personnel, who can master the start-up, bag making procedures, simple instrument debugging, changing parameters, etc.; the mechanical instrument debugging personnel must pass the manufacturer's strictness and be proficient in the performance of the instrument. Work procedure, operation mode, working state, common fault troubleshooting and handling; operation of computer instruments is strictly prohibited without personnel. The daily maintenance of the rewinder must ensure that the inside and outside of the computer instrument box is clean and dry; regularly check that the terminals are not loose or falling off. Ensure that the circuit and gas path are unobstructed.

1. The rewinder regularly checks the screws of all parts of the packaging machine to avoid loosening;

2. The rewinder pays attention to the waterproof, moisture-proof, anti-corrosion and rat-proof of the electrical parts of the rewinder. The inside of the electric control box and the terminals should be kept clean to prevent electrical failure;

3. When the rewinder is stopped, the two heat-sealing rollers should be in the open position to prevent the packaging materials from being scalded;

4.The meshing parts of each gear, the oil filling hole of the bearing seat and each moving part are filled with oil for lubrication. When adding lubricating oil, please be careful not to drip oil on the transmission belt to prevent slipping and turning or belt aging damage;

5. The transmission and moving parts must be checked and tightened within a week of use for a new rewinder. Maintenance; after that, regular inspection and maintenance must be carried out every month.

The above is an introduction to the daily maintenance and maintenance of the rewinder.