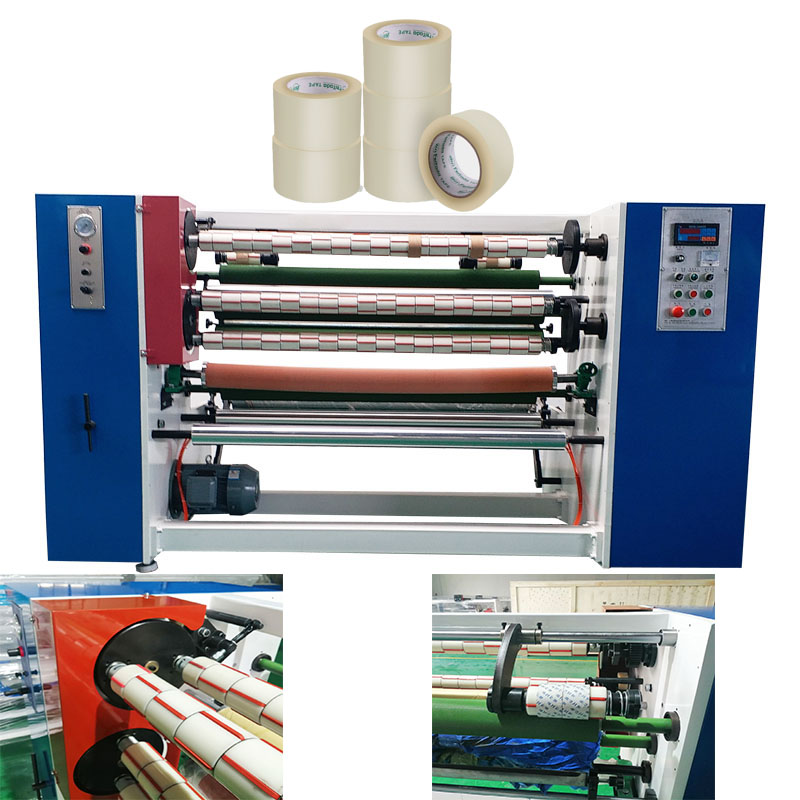

BC-212 BOPP Tape Slitting Machine

Functions and Features

- Auto tension control for unwinding and rewinding section.

- Non-stop automatic label

- It is designed for automatic loading and unloading of paper core from the rewinding shaft.

technical Parameters

| Machine width | 1000mm/1300mm/1600mm |

| Max unwinding diameter | 800mm |

| Min slitting width | 12mm |

| Max rewinding diameter | (3”shaft) 4 shafts exchange: 350mm |

| Machine speed | 0-260M/min |

| Razor | 0.2x22x60mm |

| Main motor | 5HP |

Advantages of Large Diameter BOPP Tape Slitting Machine

In the manufacturing industry, the demand for adhesive tape continues to grow, and with it comes the need for efficient, high-quality slitting machines. One of the most important machines in tape production is the BOPP tape slitting machine, which is used to accurately slit large rolls of BOPP tape into small rolls of various widths. While there are many different types of BOPP tape slitting machines to choose from, one of the most advantageous options is the large diameter BOPP tape slitting machine.

Large diameter BOPP tape slitting machines are designed to handle larger rolls of BOPP tape, typically at least 800 mm in diameter or larger. This makes it ideal for manufacturers who produce tape in bulk or who require wider tape rolls for their specific applications. The main advantage of large diameter BOPP tape slitting machines is the ability to accommodate larger rolls, which can significantly increase production efficiency and reduce downtime caused by frequent replacement of small rolls.

In addition, the large diameter BOPP tape slitting machine is equipped with advanced technology and precision engineering to ensure accurate and consistent slitting. This is critical to maintaining the quality and performance of the tape, as any inaccuracies or irregularities in the slitting process may result in a product that does not meet industry standards. With large diameter BOPP tape slitting machines, manufacturers can be confident in the reliability and accuracy of their slitting operations, resulting in higher quality end products and greater customer satisfaction.

Another major advantage of large diameter BOPP tape slitting machines is their versatility. The ability to handle larger rolls of BOPP tape gives manufacturers the flexibility to produce tapes in a variety of widths to meet a variety of customer requirements. This adaptability is crucial in today’s competitive market, where customized and tailor-made solutions are increasingly sought after. Whether it is narrow rolls for packaging or wide rolls for industrial applications, large diameter BOPP tape slitting machines can meet the diverse needs of different industries and customers.

Additionally, large diameter BOPP tape slitting machines are designed for ease of use and minimal maintenance, making them a cost-effective investment for manufacturers. With user-friendly controls and automation features, operators can easily manage the slitting process and maximize productivity. Additionally, the machine's sturdy construction and durable components ensure long-term reliability and performance, reducing the need for frequent repairs and replacements.

In summary, large diameter BOPP tape slitting machines offer numerous advantages to manufacturers in the tape industry. Its ability to handle larger rolls, precise slitting capabilities, versatility and user-friendly design make it an important tool for improving production efficiency and product quality. As the demand for tapes continues to grow, investing in large diameter BOPP tape slitting machines is a strategic move for manufacturers looking to stay ahead in the market.

Cello tape slitting rewinding machines have transformed the tape manufacturing process, providing several benefits to organizations. As mentioned, these machines improve productivity, assure exact and uniform tape widths, accommodate a wide range of tape materials and sizes, contribute to cost savings, and have user-friendly interfaces.

Accurate Engineers is the leading Cello Tape Slitting Rewinding Machine & Tape Making Machine Exporters In China that provides high-quality machines to fulfill customers’ specific needs. Businesses may enhance their tape production processes, offer high-quality products, and stay ahead in a competitive market by using these modern machines.