BC-211 BOPP tape slitting machine

Functions and Features

- The surface slitter rewinder machine adopt central control for easy operate.

- PLC and touch screen system to make sure the accurate of the rewinding length.

- Magnetic brake makes sure the length precisely when stop the machine.

- Auto shaft exchange: once two shafts rewinding finished then another two shafts auto exchange which can improve work efficiency.

- Arc stretching roller can eliminate the tape wrinkles and flat the material for feeding well.

- Cycloid big wasted rewinding about 3 jumbo roll no need discharge the waste.

- None stop rewinding shaft load and unload system for high efficiency production.

- Automatic labeling system and no need manual work, high efficiency, large production capacity.

The Cello tape by Our Slitting and Rewinding Machine

technical Parameters

| Working width | 1300/1600mm |

| Max. Rewind Diameter: | 200mm for 4 shafts; 320mm for 2 shafts |

| Max. Unwind Diameter | 700/800mm |

| Paper Core inside diameter | 3'' (76.2mm) |

| Min. Cutting Width | 12mm |

| Slitting System | Razor Blade (Air score knife optional) Blade: 0.2mm x 22mm x 60mm |

| speed | 0-260m/min |

| Electricity | 380V, 50HZ (or according to customer requirement ) |

| Power | 4kw |

| Dimension | 2550mm * 1450(1650)mm * 1700mm |

Other specification optional according to the demand.

Adhesive Tape Slitting Machine Spare Parts

- Mould

- Nylon sleeve

- blades

- Label

- razors

- PVC pipe

auto label BOPP tape slitter function

The working principle of the automatic label slitting machine is to use sensors and cutting mechanisms to detect and accurately cut the labels on the bopp tape passing through the machine. This eliminates the need for manual intervention, reduces the risk of human error and ensures consistent results. The machine can be programmed to detect specific label patterns, sizes and locations, making it highly customizable to meet the unique requirements of different products and industries.

In addition to automatic labeling capabilities, bopp tape slitting machines offer a range of other advantages. These machines are designed to operate at high speeds for maximum productivity and output. They are also equipped with cutting-edge control systems to ensure smooth and reliable performance. This in turn reduces downtime and maintenance requirements, resulting in cost savings for manufacturers.

Another major advantage of bopp tape slitting machines is their versatility. These machines are capable of handling a variety of bopp tape materials, including different widths and thicknesses. Whether for industrial packaging, consumer goods or other applications, this machine can efficiently process different types of bopp tapes, making it a valuable asset for businesses with diverse product lines.

Additionally, bopp tape slitting machines are designed with operator convenience in mind. It comes with user-friendly interface and controls, making it easy to set up and operate. This minimizes the need for extensive training and enables operators to quickly adapt to the machine, maximizing its potential from day one.

Overall, the combination of a bopp tape slitting machine with automatic label slitting capabilities provides a comprehensive solution for businesses looking to process bopp tape efficiently and accurately. The advanced technology and capabilities of these machines make them valuable assets to manufacturers in various industries. Investing in a BOPP tape slitting machine with automatic label slitting can streamline the production process, improve product quality, and improve overall efficiency, making it a smart decision for businesses looking to stay competitive in today's market.

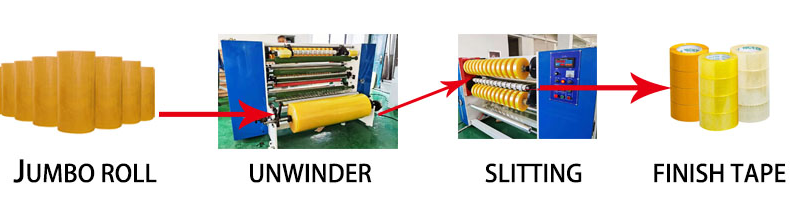

What is tape slitting?

Tape slitting is the process of cutting a master 'log' roll of tape down into smaller rolls of tape. With our state of the art facilities we can provide tapes to your exact measurements. We are able to slit tapes as narrow as 3mm and up to 1600mm wide (the usual maximum 'log' width).

What industries are slit adhesive tape rolls suitable for?

Custom slit rolls of adhesive tapes are common in the fabrication of metal components, powder coating, print, point of sale, signage and automotive industry.

What are the minimum and maximum sizes of tapes you can slit?

We can slit log rolls of tape from 3mm and up to 1600mm wide. The maximum diameter of a 'log' roll we can is slit is 450mm.